Ebook's

Content

Field dismounting of the Enfield No 2

revolver

- Exploded

view and parts nomenclature

- Barrel turned down on its hinge

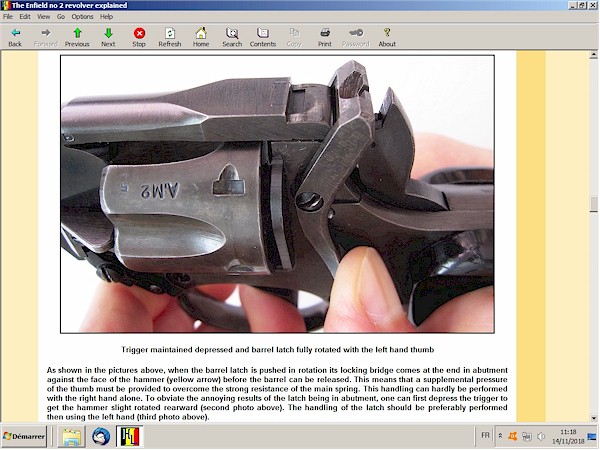

- Locking latch in abutment against the hammer face

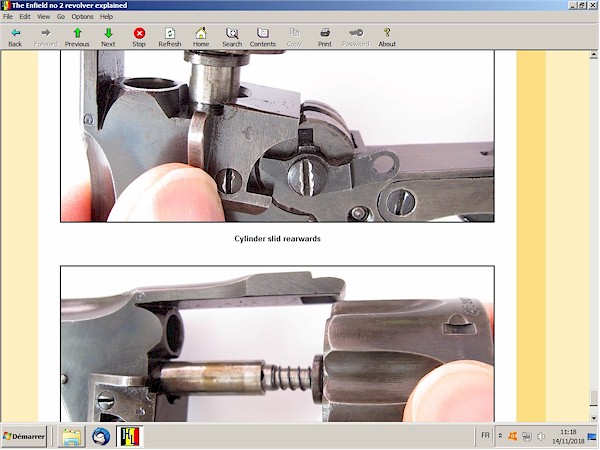

- Dismounting of the cylinder

- Lever of the cylinder catch unlocked

Advance

dismounting of the Enfield No 2 revolver (1)

- Disassembly

of the cylinder unit

- Ejector nut unscrewed

- Dismounting of the cylinder catch and lever

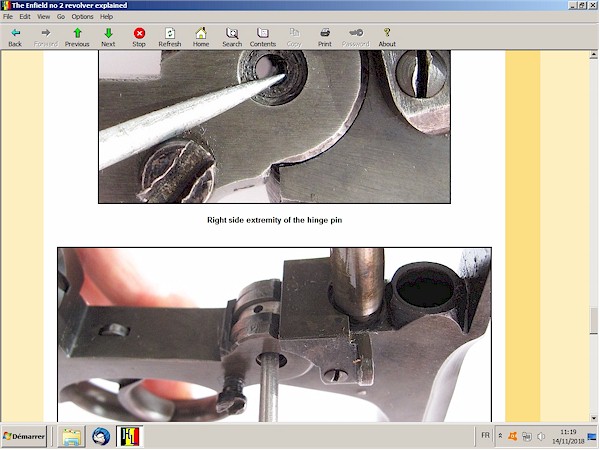

- Dismounting of the barrel hinge pin

- Separation of the barrel unit from the frame

Advance

dismounting of the Enfield No 2 revolver (2)

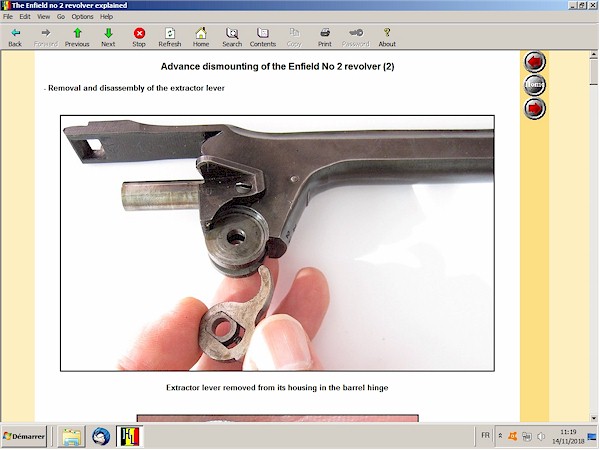

- Removal and

disassembly of the extractor lever

- Dismounting of the cylinder catch

- Dismounting of the front sight

- Dismounting of the cylinder axis

- Detachment of the grip plates

Advance

dismounting of the Enfield No 2 revolver (3)

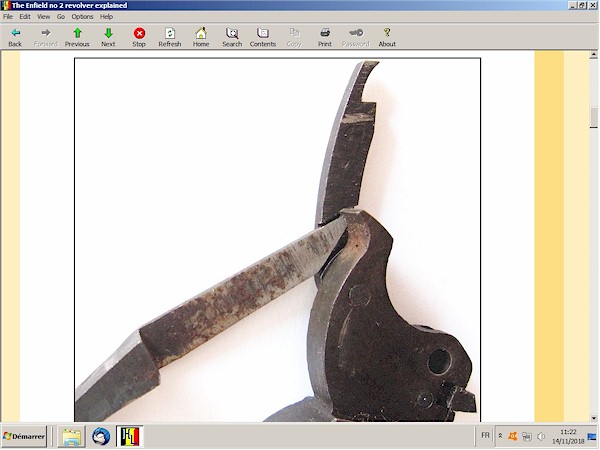

- Dismounting

of the barrel latch

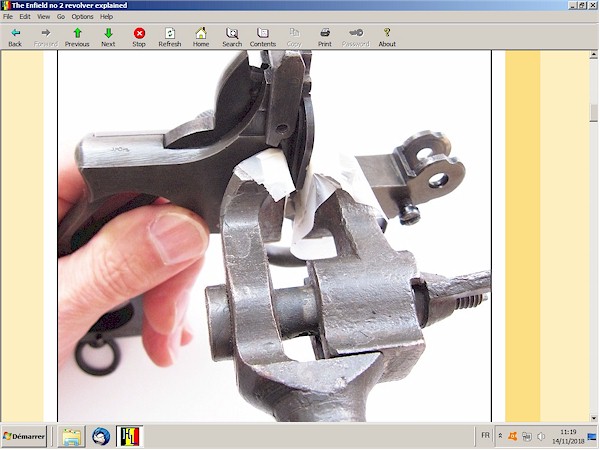

- Hand vise squeezing the V-shaped return spring

- Detachment of the side cover plate

- Dismounting of the main spring

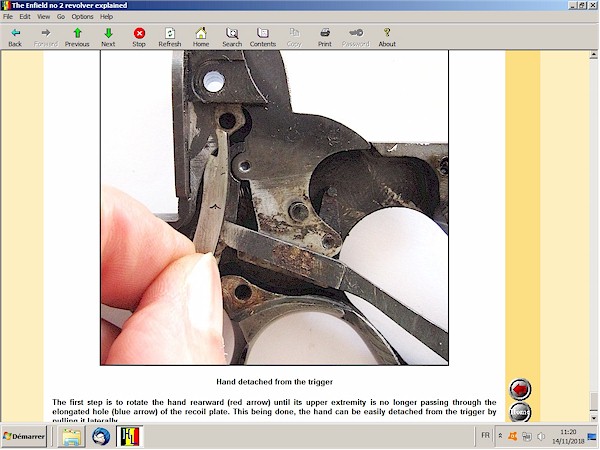

- Dismounting of cylinder hand

Advance

dismounting of the Enfield No 2 revolver (4)

- Dismounting

of the rebound lever

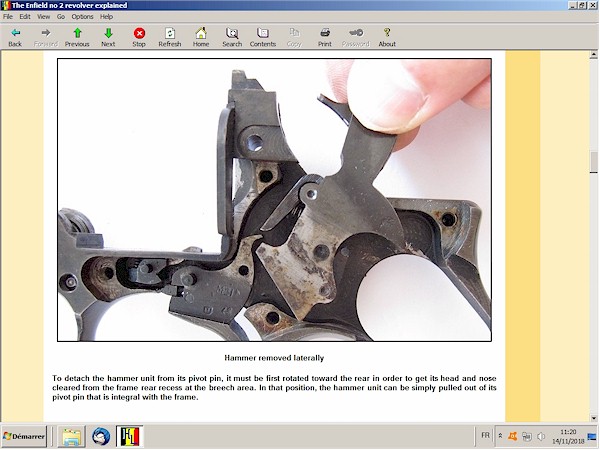

- Dismounting of the hammer unit

- Dismounting of the trigger

- Dismounting of the cylinder stop

- Dismounting of the recoil plate

- Dismounting of the lanyard ring

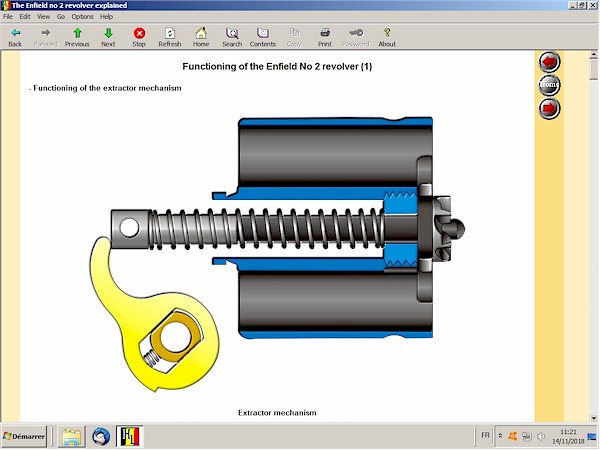

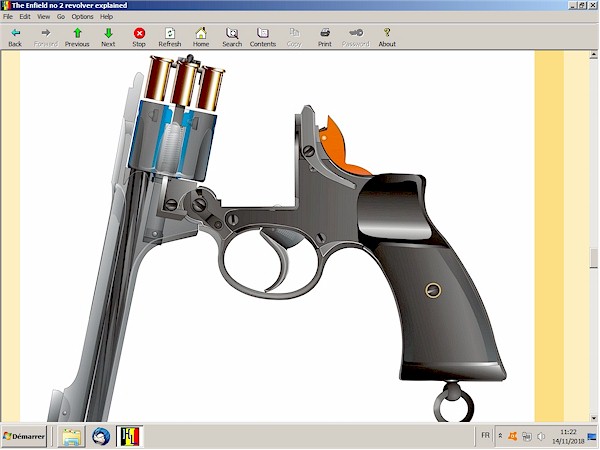

Functioning

of the Enfield No 2 revolver (1)

- Functioning

of the extractor mechanism

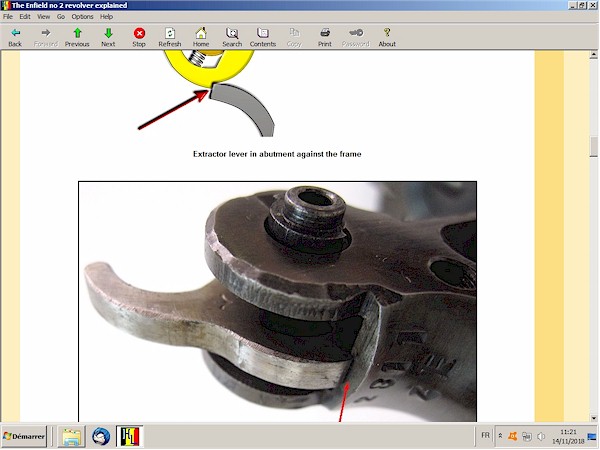

- Extractor lever in abutment against the frame

- Extractor being lifted by the barrel rotation

- Barrel unit rotated back to its initial position

Functioning

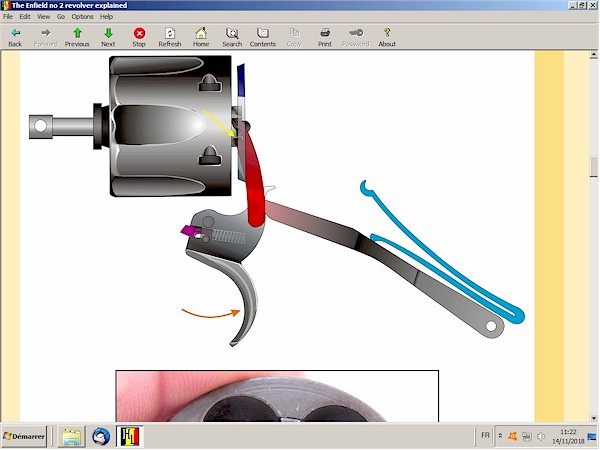

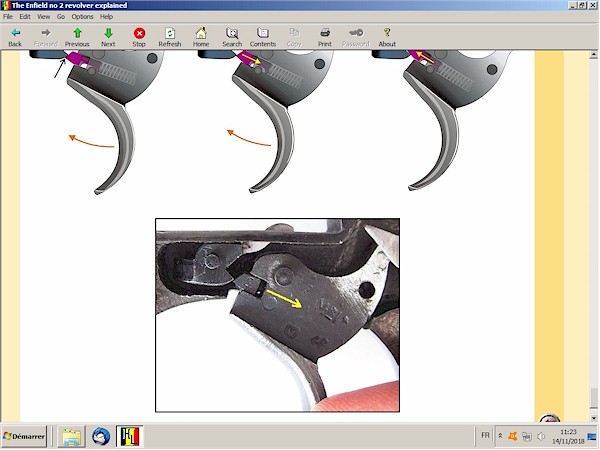

of the Enfield No 2 revolver (2)

- Functioning

of the trigger mechanism

- Rotation of the cylinder

- Rebound lever engaged in the cut of the hand

- When the trigger is depressed

- Locking and unlocking of the cylinder

- Interaction of the trigger with the cylinder stop

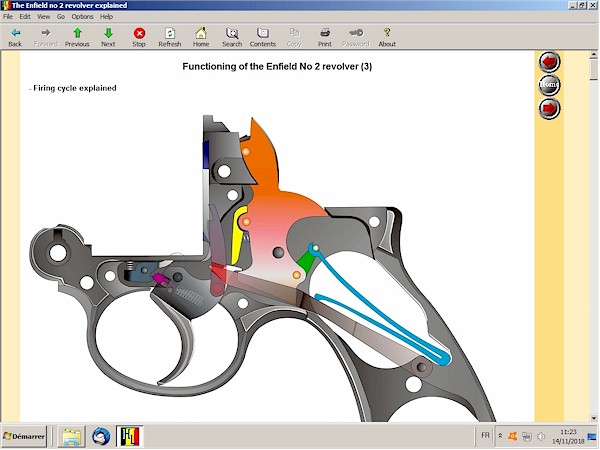

Functioning

of the Enfield No 2 revolver (3)

- Firing cycle

explained

- Early stage of the firing sequence

- Hammer released and beginning its forward fall

- Explosion of the cartridge in line

- Return of the trigger to its initial position

- Action of the rebound lever

- Hammer breast in abutment against the safety

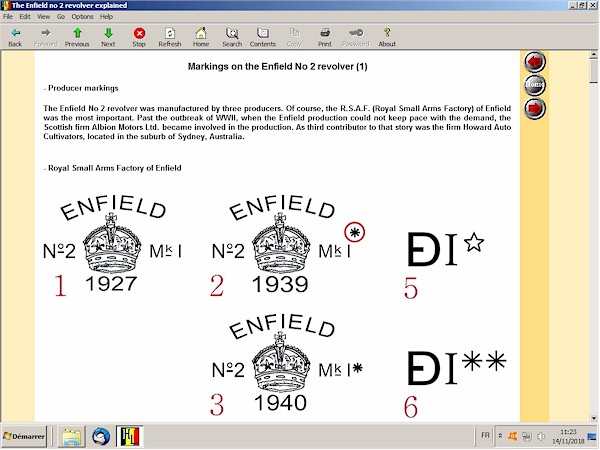

Markings

on the Enfield No 2 revolver (1)

- Producer

markings

- Royal Small Arms Factory of Enfield

- Albion Motors LTD (in Scotland)

- Howard Auto Cultivators (Australia)

- The serial number

- The letter prefix before the serial number

Markings

on the Enfield No 2 revolver (2)

- Military

proof markings

- Commercial proof markings

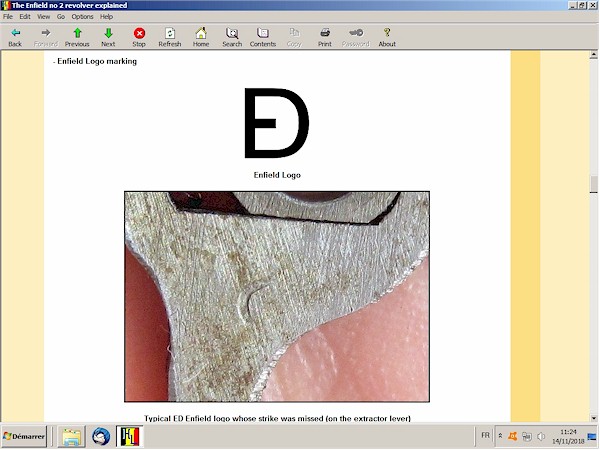

- Enfield Logo marking

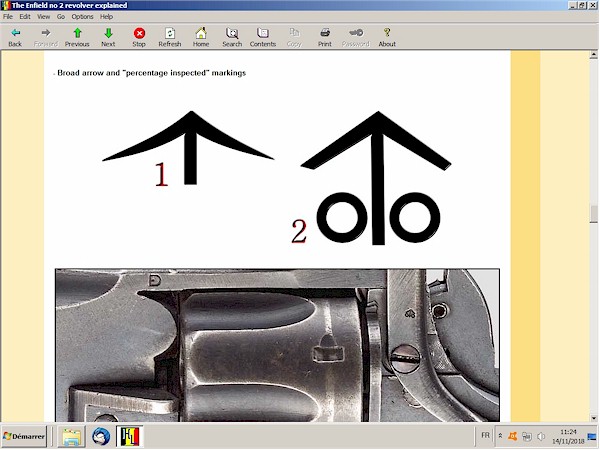

- Broad arrow and "percentage inspected" markings

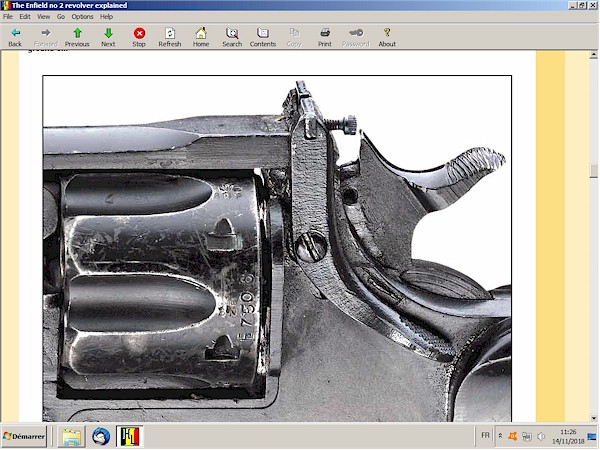

- Steel batch code on the cylinder

- Mark I** marking on hammer and trigger

- Inspector stamps

- Various letters and numbers

- Military unit markings

Markings

on the Enfield No 2 revolver (3)

- D.P. (Drill

purpose) and UNSERV (unserviceable) markings

- Canadian Military ownership marking

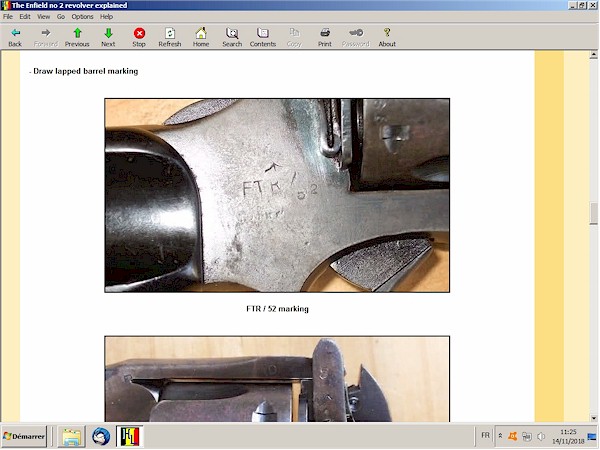

- FTR (Factory Thorough Repair) marking

- Draw lapped barrel

marking

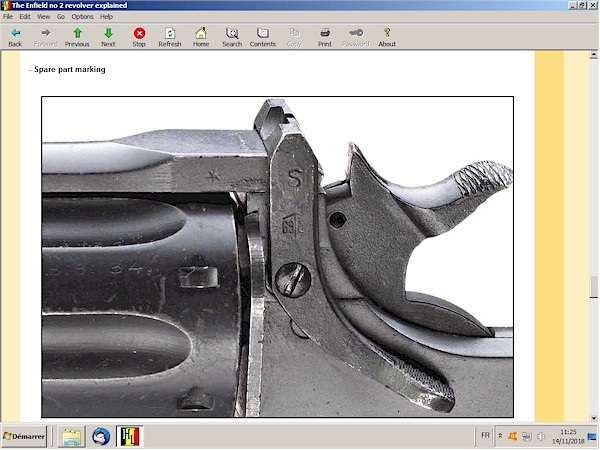

- Spare part marking

- Modification or repair of the barrel and/or sights

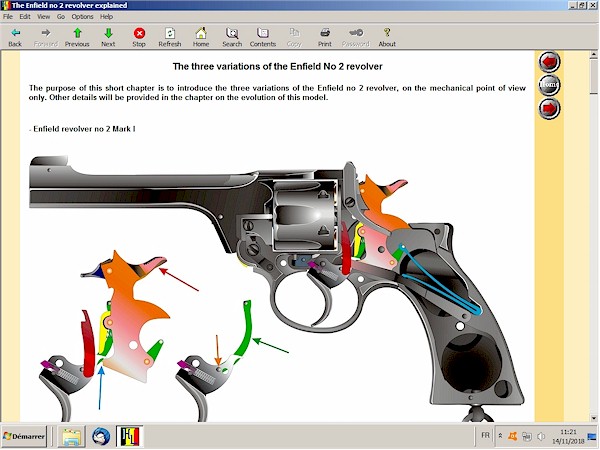

Story

and evolution of the Enfield No 2 revolver (1)

- Webley &

Scott Mark III revolver in .38 S&W

- Webley & Scott Mark IV in .38 S&W

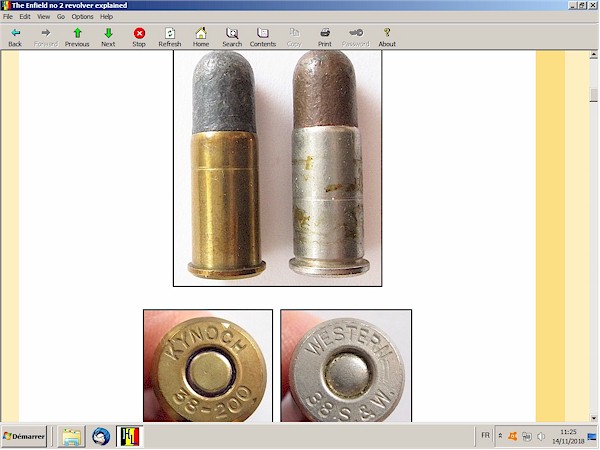

- Kynoch 38-200 cartridge

- Pistol Revolver ENFIELD .380" experimental

- The production drawings of June 1923

- Tests of November 1927

- Enfield no 2 Mark I with removable rear sight

- Two variations of the adjustable rear sight

- Mark I checkered walnut grip plates

- Second type of walnut grip plates with serrations

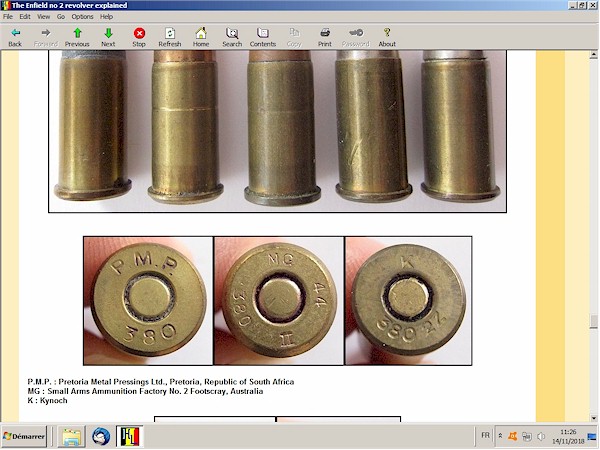

- Blank, drill, and proof cartridges

- Trials of end of 1930 - early 1931

- Hammer safety by Capt. Boys

Story

and evolution of the Enfield No 2 revolver (2)

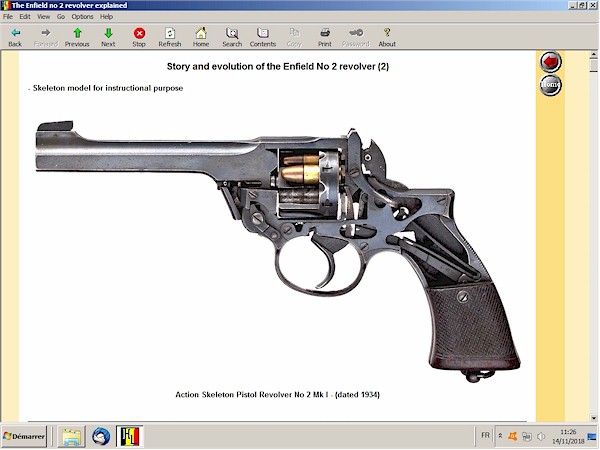

- Skeleton

model for instructional purpose

- .22 caliber version of the No 2 Mk I

- Parker Hale .22 conversion

- Appearance of the No 2 Mark I* variation

- Mark II serrated wood grip plates

- Mark II walnut right side plate fitted with the early screw nut

- Appearance of the No 2 Mark I** variation

- Mark III Bakelite grip plates

- Wartime production by the Scottish firm Albion Motors Ltd.

- Production of the firm Howard Auto Cultivators

- Development of the No 2 Mk I Revolver at Howard Auto Cultivator

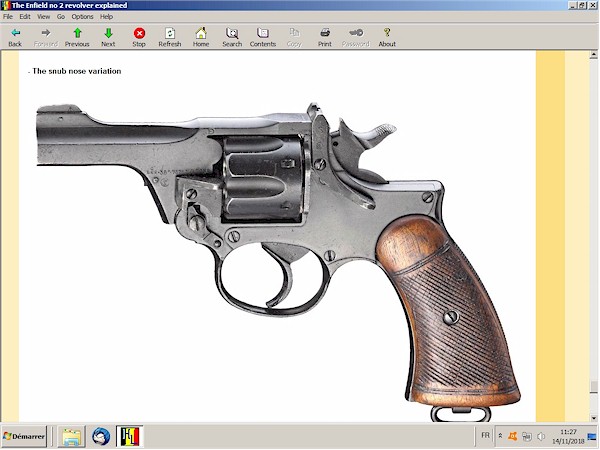

- The snub nose variation

Ebook screen prints

|